As we've said in previous posts, we're aiming to get the bodywork on before Winter, but there are a few jobs that'll be easier to do without it on. The aim today was to get those done, but it didn't quite work out that way:

We started by trying to work out where the cooling system hoses will go - certainly not where the standard manual says! It looks like the recently-acquired "Aerorace" manual is the best bet, although it won't be exactly right as that model has no heater. Anyway, we fitted the pipes between the bottom connection on the radiator and the water pump before realising that the rest of the pipework will be best done after the exhaust manifold has its final fitting..... which can't be done until after the bodywork's on!

So we moved onto the clutch cable, which was relatively easy once we'd removed the pedal pivot to provide some extra travel on the inner cable so that the grommet on the clutch arm could be pushed over it before being re-fitted to the arm. We now appear to have a working clutch:

|

| Clutch cable through the grommet in the actuator arm |

Next up was the long-awaited bracket for the speedometer transducer (the manual said it should have been welded to the chassis, but it was missing). The bracket went on nicely once we'd put a couple of rivnuts in the chassis, but we're not convinced it puts the transducer near enough to the driveshaft bolts it'll need to "sense" as they turn to work out the speed. We tried to bend the bracket, but it's tougher than any of the vices we have, so we'll have to have another go it if it turns out to be a problem.

|

| Transducer above the RHS driveshaft bolts |

We then made up a template for the hole we'll need to make in the side of the body for the exhaust manifold to go through. Not looking forward to that job!

|

| Template for the exhaust manifold hole made from the radiator box |

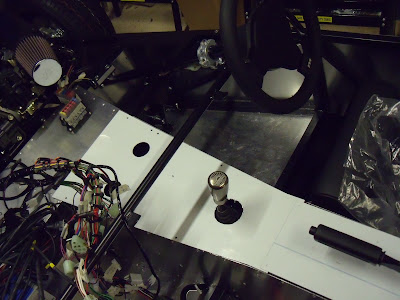

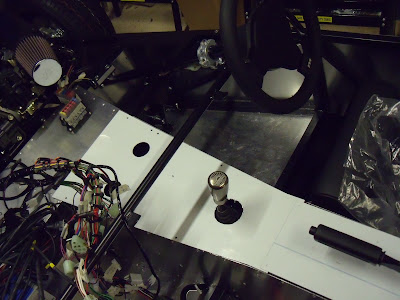

We also made the gearlever hole in the aluminium plate that will cover that area. It'll need enlarging, but we wanted to put it in place so we can work out which holes will be used for the engine wiring.

G G |

| Gearbox cover plate in (temporary) place |

We then went back to the fuel pump and decided that it would definitely need the bracket turing around to allow a straighter run for the fuel pipes. This turned out to be easier said than done, as one of the new rivnuts refused to lock in place properly despite numerous attempts. We need to find a way of tightening it up.... next time.